Innovative transport technology & load securing for the precast industry

Our system solutions at a glance

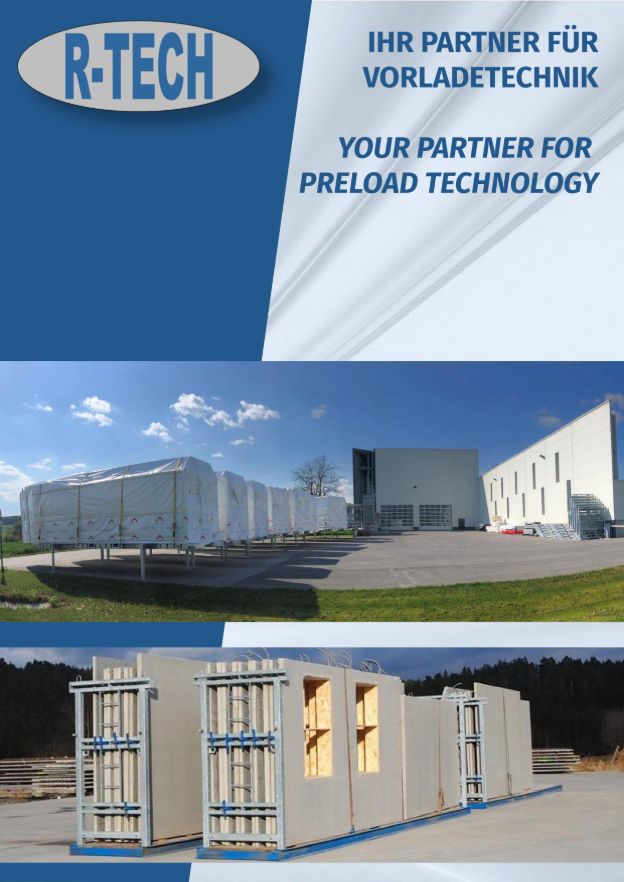

R-Tech’s transport technology and load securing solutions make the transportation of components plannable and safe. This includes the right technology for loading, securing and handling, tailored to practical use and robust processes in day-to-day operations.

Below you will find an overview of the most important areas: Internal loader pallets as transport racks for the safe transportation of prefabricated parts, swap bodies for timber construction and swap bodies for concrete construction as system solutions for flexible logistics, the turning trestle as a turning device for prefabricated concrete parts and special pallets for special requirements. In addition, glass ILP for glass and the A Bock as a proven means of transportation are linked so that you can jump directly to the appropriate detail page.

Why R-Tech? Your experts for transport technology & load securing

In the modern precast industry, time and safety are the decisive currencies. The transport of precast concrete elements weighing several tons or voluminous timber construction elements does not forgive mistakes. As a specialist with many years of experience, R-TECH Stahlbau GmbH offers solutions that start exactly where standard systems reach their limits.

30 years of experience in precast concrete and timber construction

Our transport systems are not a product of chance, but the result of over three decades of close cooperation with the construction industry. We understand the structural challenges and logistical processes in your factory and on the construction site.

What sets R-Tech transport systems apart:

Maximum safety thanks to our own test procedures: We don’t just rely on calculations. Our inloader pallets and swap bodies are tested in practical stability tests to guarantee maximum stability under real conditions.

Durability thanks to robust steel construction: our products are designed for tough, daily use. For us, “Made in Austria” stands for manufacturing quality that minimizes maintenance costs for years to come.

Increased efficiency in logistics: thanks to innovative details such as our special plastic-coated safety sword, we avoid transport damage to your components and massively speed up the loading and unloading process.

Individual special solutions: Whether it’s a special turning frame or customized special pallets – we develop transport solutions that integrate seamlessly into your production flow.

Transport technology and load securing briefly explained

Key terms that often occur together in practice are linked below. These ten short questions will give you a quick overview of what the individual solutions from R-Tech are intended for and how they are used in finished part transportation.