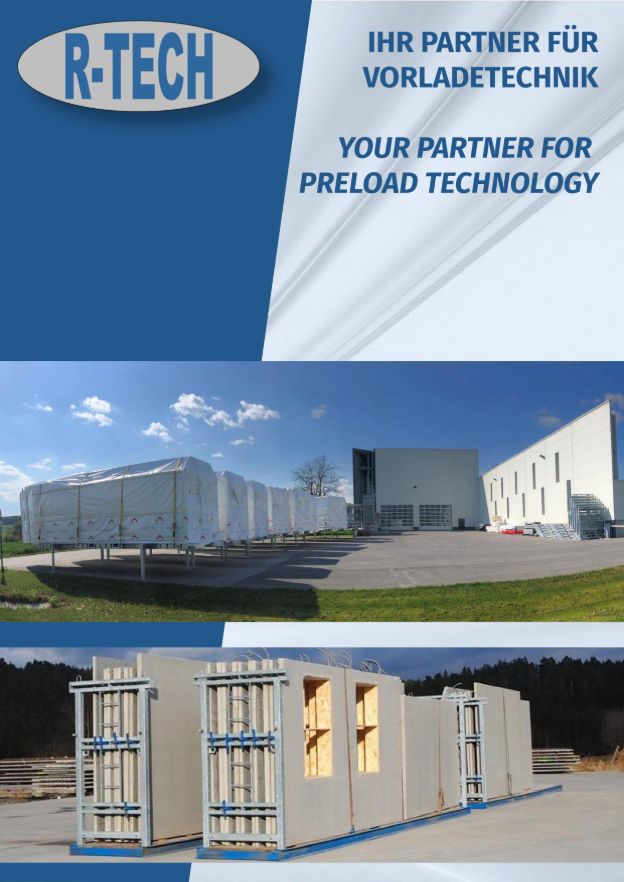

Swap bodies for timber construction: flexible logistics without waiting times

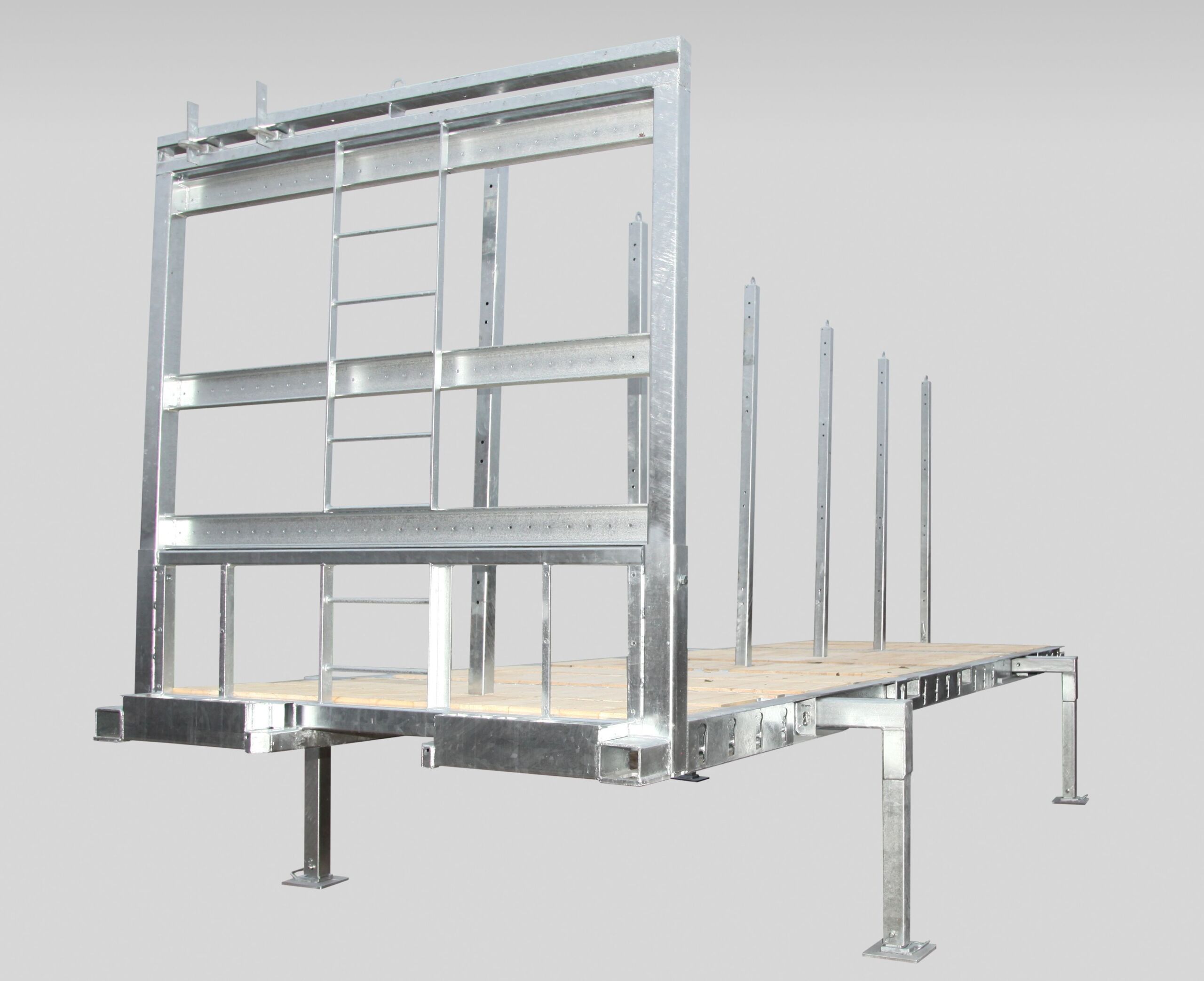

The user-optimized transport racks specially designed for the prefabricated timber industry

Efficiency is the key to success in modern timber construction. With R-TECH’s swap bodies for timber construction, you can decouple your production from transportation and create a smooth logistics process. Our systems are designed as high-quality BDF swap bodies and are specially constructed for the safe transportation of wall and ceiling elements. They offer you maximum flexibility – from the factory to the construction site.

Universally applicable: The R-TECH BDF system

No more rigid transport solutions. Our BDF swap bodies are characterized in particular by their telescopic support legs, which make transport universally possible. No matter which fleet you use or commission – our swap bodies fit on all standard system carriers:

Standard semitrailer tractor (pick-up height 1,200 mm)

Mega trailer (pick-up height 1,000 mm)

Low-bed trailer (pick-up height 800 mm)

This compatibility guarantees you independence in your choice of forwarding agent and noticeably reduces your logistics costs.

R-TECH stacking pallets for prefabricated timber construction

Lengths

7,450 mm; 7,650 mm; 8,000 mm; 9,000 mm; 10,000 mm; 12,200 mm

Width

2,550 mm or on customer request Standard container width: 2,438 mm

Entry chute

Overall height

Payload

Support height for transportation

600 or 700 mm

170 mm

20,000 kg

300 – 1,300 mm

Your advantage: increased capacity and reduced costs

The use of R-TECH swap bodies radically optimizes your processes. Use the swap bodies as flexible temporary storage directly in your production hall or on the factory premises.

No standing times: Load in the hall, protected from the weather and without time pressure. The truck does not have to wait, but simply picks up the fully loaded BDF bridge (“drop & swap”).

Product protection: Your high-quality wooden elements are only handled twice – once from production to the frame and once from the frame to assembly. This minimizes transport damage and reworking.

Durability: Like all R-TECH products, our swap bodies are designed for tough continuous use – robust, durable and low-maintenance.

Would you like to optimize your timber construction logistics? Let’s talk about your requirements. We will be happy to advise you on the right dimensions and equipment.