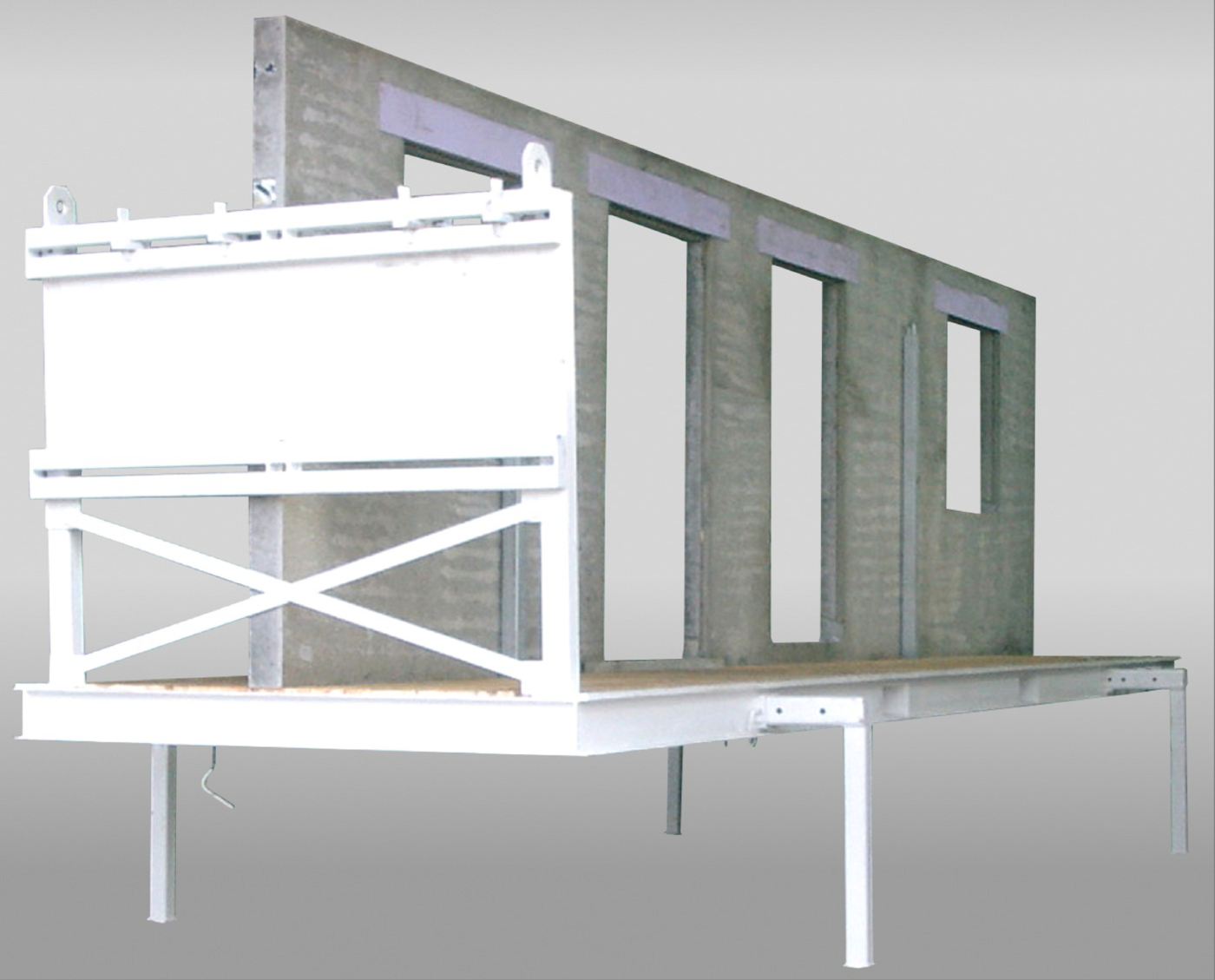

Swap bodies for concrete construction: heavy-duty logistics up to 25 tons

Transport racks specially optimized for the precast industry.

In modern construction, two things count: adherence to deadlines and maximum load capacity. These swap bodies for concrete construction from R-TECH were developed specifically for the transportation of heavy precast elements. With an enormous payload of up to 25 tons, our reinforced BDF systems offer the most robust solution on the market to make your logistics flexible and economical.

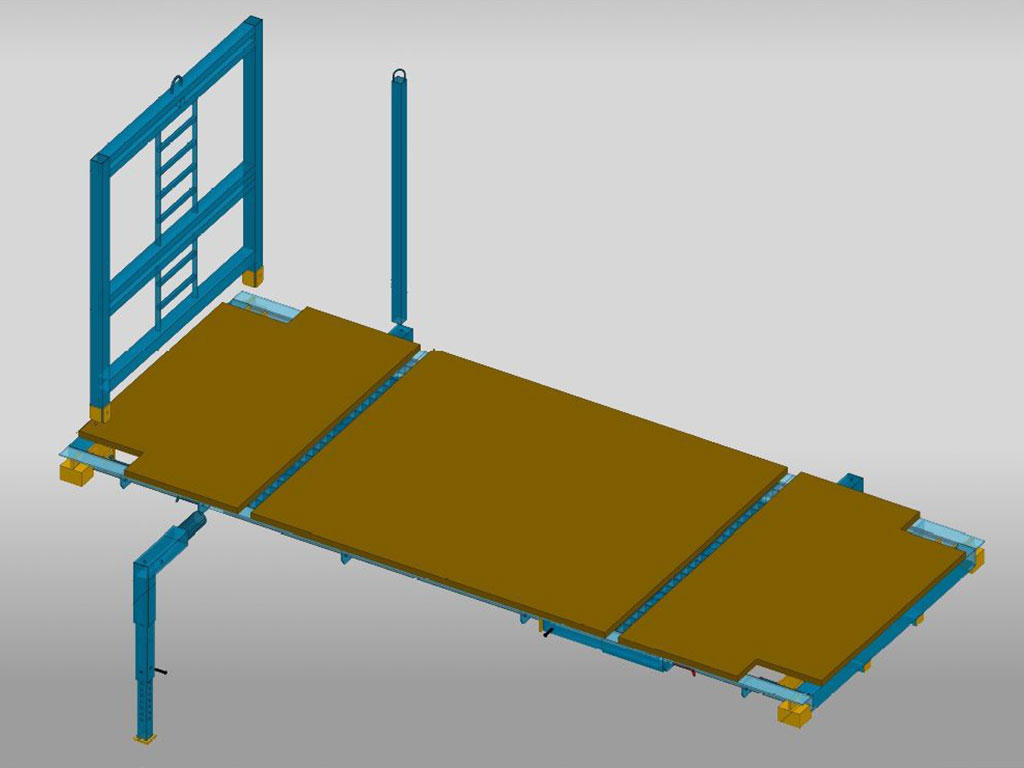

The powerhouse for your logistics: BDF systems

While standard solutions often reach their limits, the performance of our heavy-duty units is just beginning. Thanks to the telescopic support legs and the standardized design, you remain completely independent in your choice of carrier. Our swap bodies for concrete construction are compatible with all common vehicle types:

- Standard semitrailer tractor (pick-up height 1,200 mm)

- Mega trailer (pick-up height 1,000 mm)

- Low-bed trailer (pick-up height 800 mm)

Length

Width

Entry chute

Overall height

Payload

Drop height for low loader

6,000 and 8,200 mm

2,438 mm

600 or 700 mm

180 mm

25,000 kg

600 – 1300 mm

according to customer requirements

Designed for the highest loads

Precast concrete parts place extreme demands on the equipment. Our swap bodies for concrete construction are therefore more solidly constructed than conventional models:

High load capacity: Safely transport up to 25 tons of load weight per bridge.

Torsionally rigid: The reinforced frame construction prevents deformation, even under point loads from heavy pillars or beams.

Tailor-made: We offer lengths from 7.45 m to 13.60 m – precisely tailored to your components.

Your benefit: Increased efficiency in the factory and on the construction site

Use our swap bodies as mobile interim storage. Decouple your production from transportation and avoid expensive truck downtimes.

Production: Load the bridges directly at the end of the production line – without time pressure.

Logistics: The truck picks up the waiting, full bridge (“drop & swap”) and drives off immediately. No waiting time for the driver.

Construction site: The bridge can be parked on site while the truck is already picking up the next load. The material is available to the fitters exactly when it is needed.

Are you looking for a transport solution that can withstand the heaviest loads? Talk to us about your concrete construction requirements. We will configure the optimum swap body for your fleet.