Internal loader pallets from R-TECH

When perfection meets burden

The transportation of precast concrete and timber elements is not a variable variable, but an equation in which the parameters of safety, efficiency and material integrity must be uncompromisingly fixed. Conventional transportation methods often fail due to the tension between dead weight, payload requirements and the mandatory torsional rigidity. The kinetic energy acting on fragile loads during road transportation requires a passive but high-strength counter-structure. If this is not the case, the resulting stresses inevitably lead to micro-cracks or structural defects that force reworking on the construction site. Here, the Innenlader pallet acts not only as a carrier medium, but also as a highly specialized, statically relevant component of the entire logistics process.

R-TECH is committed to raising this static relevance to the level of a primary industrial standard. We view the pallet as a precision-engineered component whose specification goes beyond simply holding the load. Our inloader pallets are constructs that do not yield to the physical laws of heavy load transportation, but master them. They transfer the vertical and horizontal forces acting on them via an optimized geometry and thus ensure that the transported components retain their shape. This ensures quality assurance even before they arrive at their destination.

Innenlader range – The R-TECH quality promise

An inloader pallet is a specialized swap body design, primarily used in heavy-duty intermodal transport for the transportation of large-sized, vertically stored precast elements. The R-TECH systems effectively eliminate these potential torsional forces in order to deliver sensitive loads (such as high-precision brick walls or delicate thin-walled concrete elements) without damage, even under dynamic driving conditions. The basis for this mechanical insensitivity is the consistent use of high-strength structural steel of grade S355JR. This material offers a significantly higher yield strength than conventional structural steels, which enables a lighter construction with maximum rigidity. This precise use of materials guarantees rework-free durability in continuous operation and ensures the cost-effectiveness of the means of transport for decades.

Highest safety standards

through our own safety tests

Safety requirements are defined differently internationally. We set standards that are right. We counteract the risk of tipping in gusts of wind, damage during transportation or movement with innovative, tested systems.

Practical tests have been carried out for set-down pallets, swap-body platforms and inloader pallets, giving you the certainty that everything will run smoothly for man and material on the construction site. We at R-TECH have exclusively developed telescopic inloader pallets especially for the FAYMONVILLE PREFAMAX telescopic inloaders. Efficiency and safety are not mutually exclusive. See for yourself what our inloader pallets can do.

Proven stand safety system

Safe goods and accident prevention

Large construction site after a heavy storm, where the extreme case – the domino fall of walls onto inloader pallets – can be seen. This serial accident involving several inner loader pallets with walls continued until it hit R-TECH inner loader pallets with a support system. Our stand securing system proved itself to such an extent that not only were the goods on the pallet secured, but this accident was stopped.

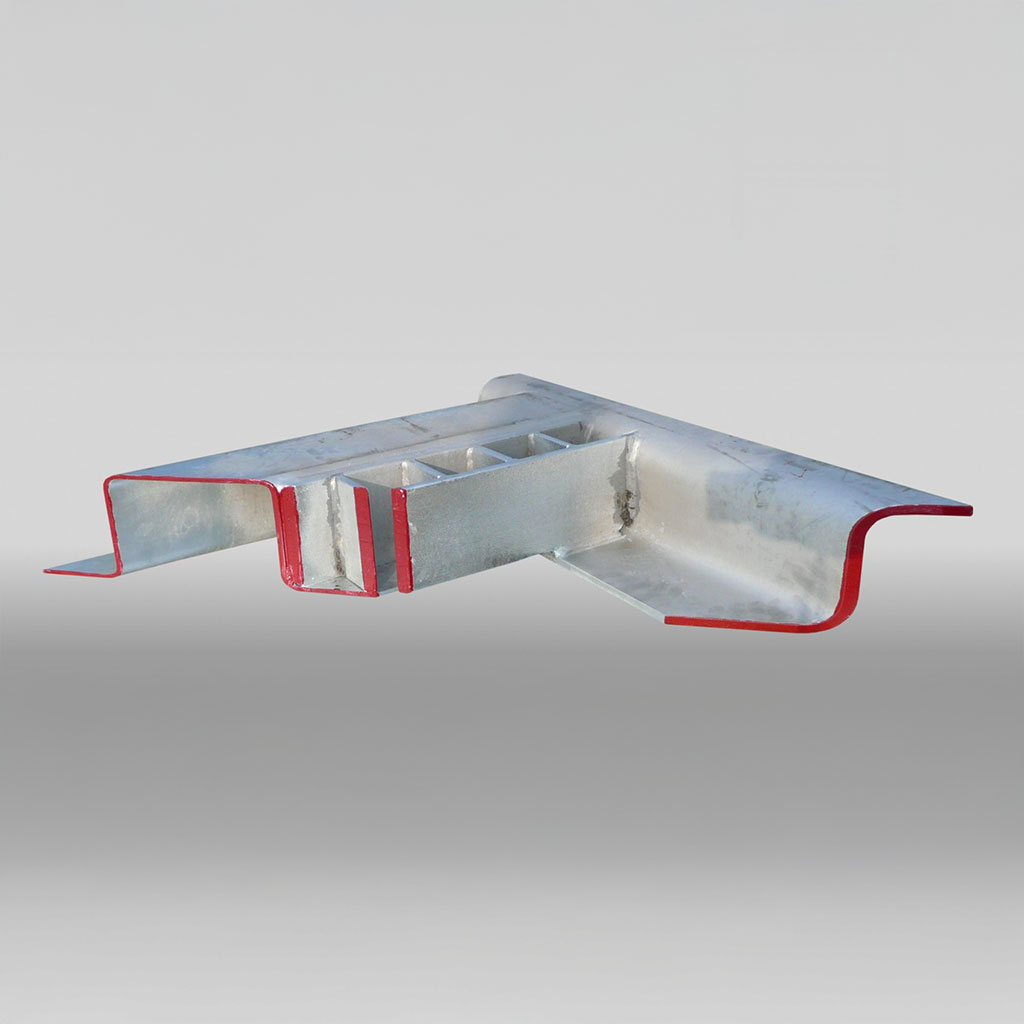

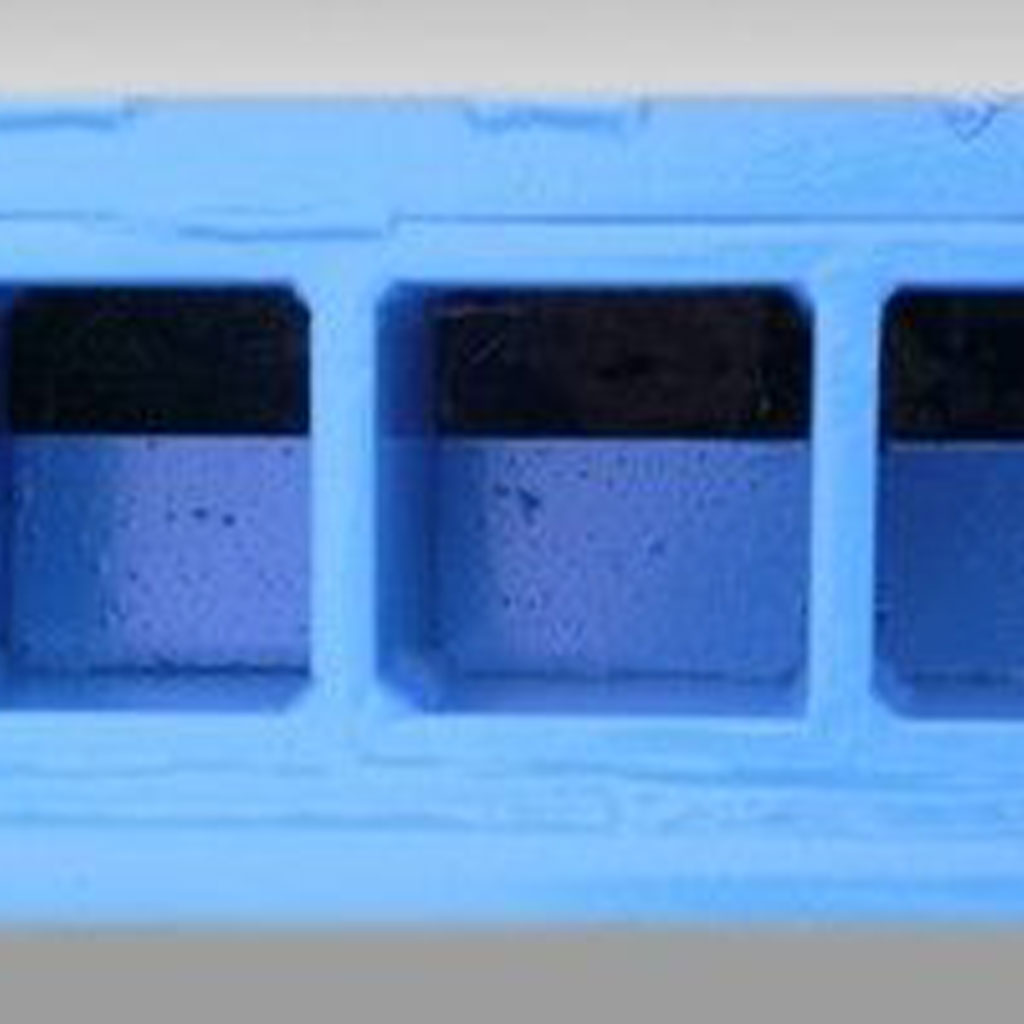

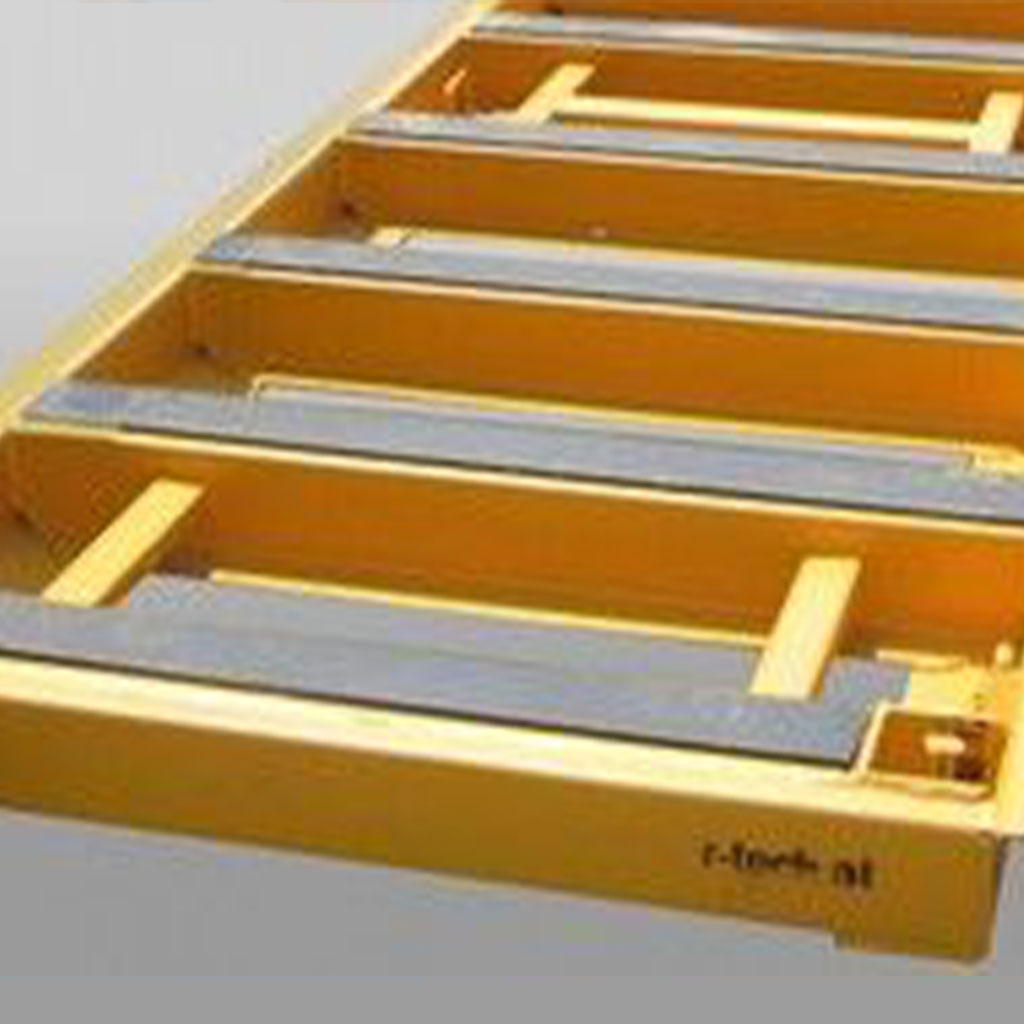

Base frames in Standard and Extra Robust

We are versatile and able to support individual concepts with special dimensions and requirements. We offer inloader pallets in 2 variants:

1. standard

Your advantage: cost-effective, proven design with optimum adaptation to the transport load for permanent, rework-free, heavy-duty use, with all necessary safety standards, with static test report

C – Side member made of standard rolled section S355 JR

I– Cross member made of standard rolled section S235 J

Our cost-effective inloader pallet is optimally adapted to the load to be transported. It is designed for long-term, rework-free, heavy-duty use and meets all the necessary safety standards.

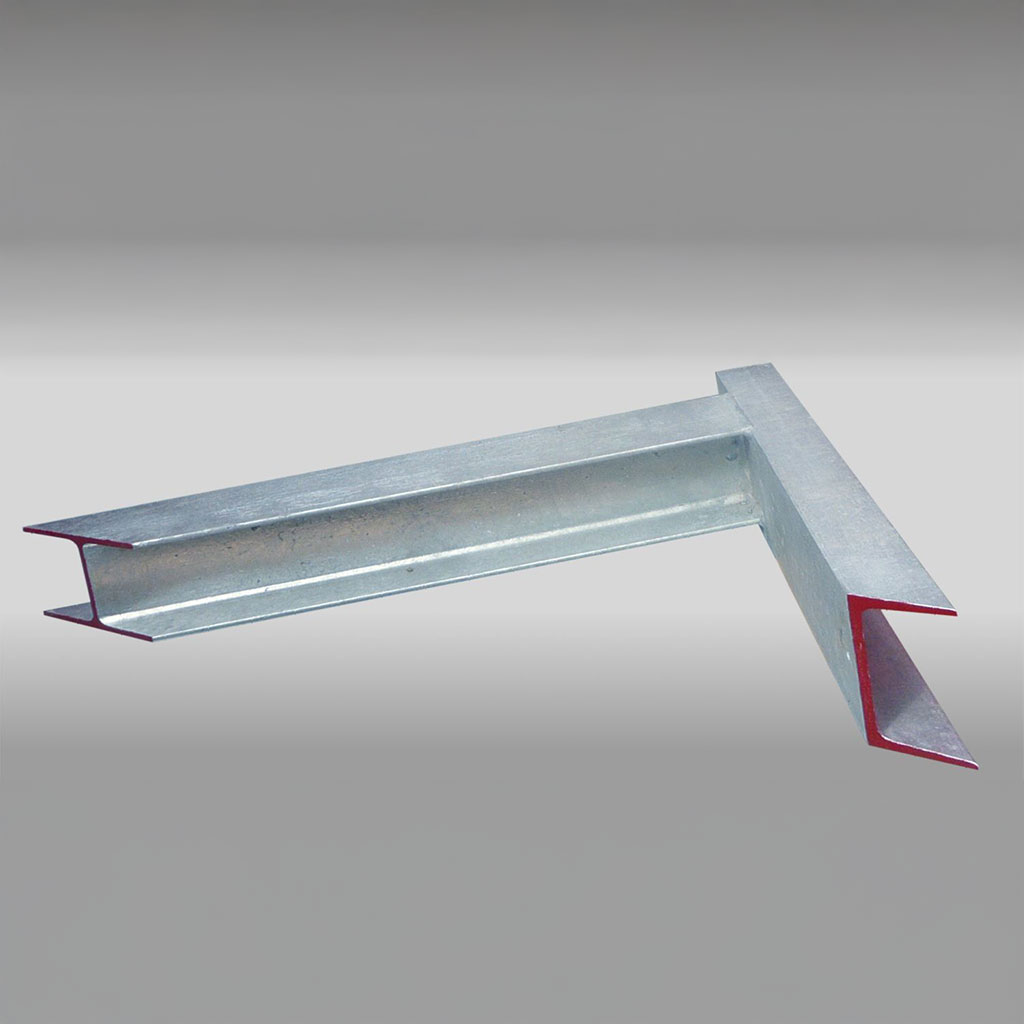

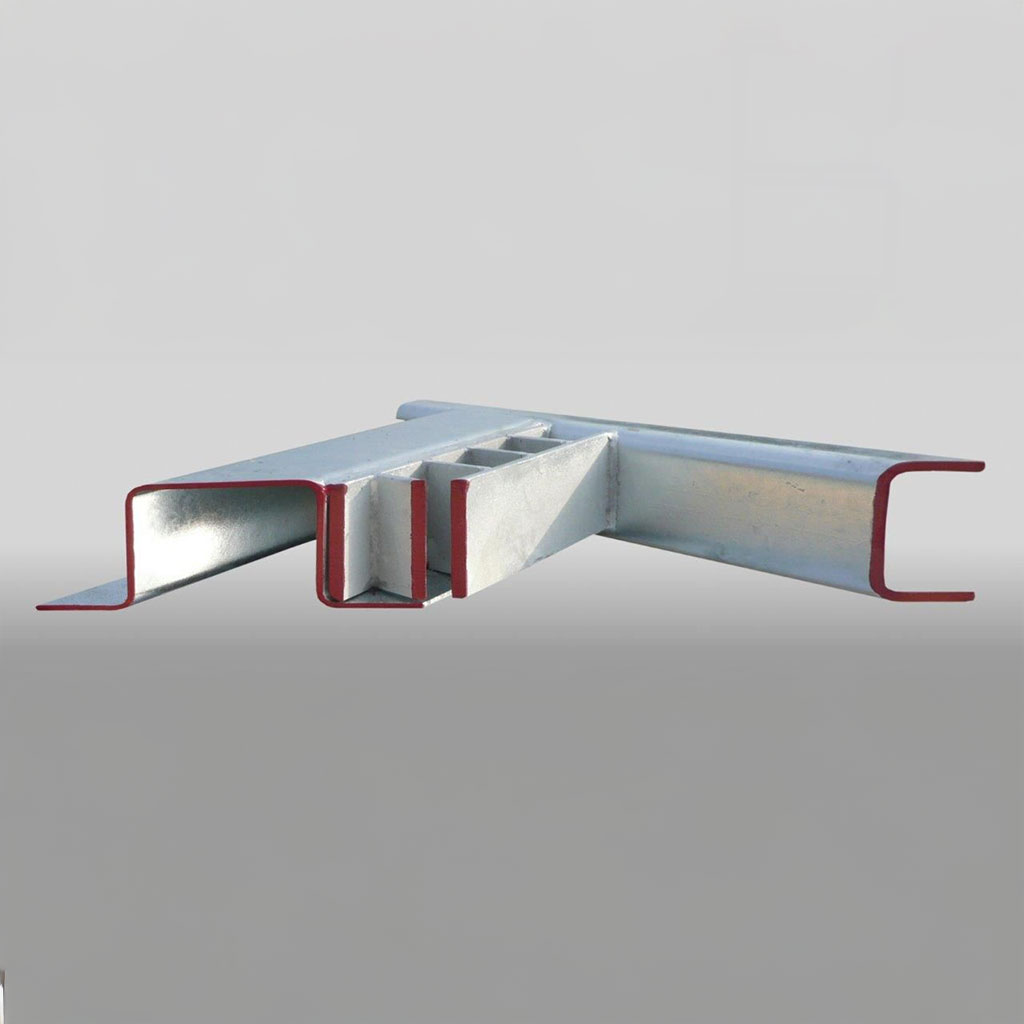

2. extra robust

Your advantage: lightweight construction with maximum load-bearing capacity and torsional rigidity, EN statically tested

1st choice for the transportation of sensitive walls, e.g: Brick walls, thin walls, fragile walls and generally the optimum solution for robust, long-term use

Main longitudinal beams made of folded high-strength steel sheets in Z or U shape. Cross beams made of high-strength steel sheets in omega shape. Load capacity per cross member 14 tons, statically tested!

U – Curved side member made of 12 mm sheet metal S355 JR, alternatively also from 6 mm

Ω – Cross member made of 6 mm sheet metal S 355 JR

Z – Curved side member made of 12 mm sheet metal S355 JR, alternatively also from 6 mm

Ω – Cross member made of 6 mm sheet metal S 355 JR

Our safety standard

We are versatile and able to support individual concepts with special dimensions and requirements. We offer inloader pallets in 2 variants:

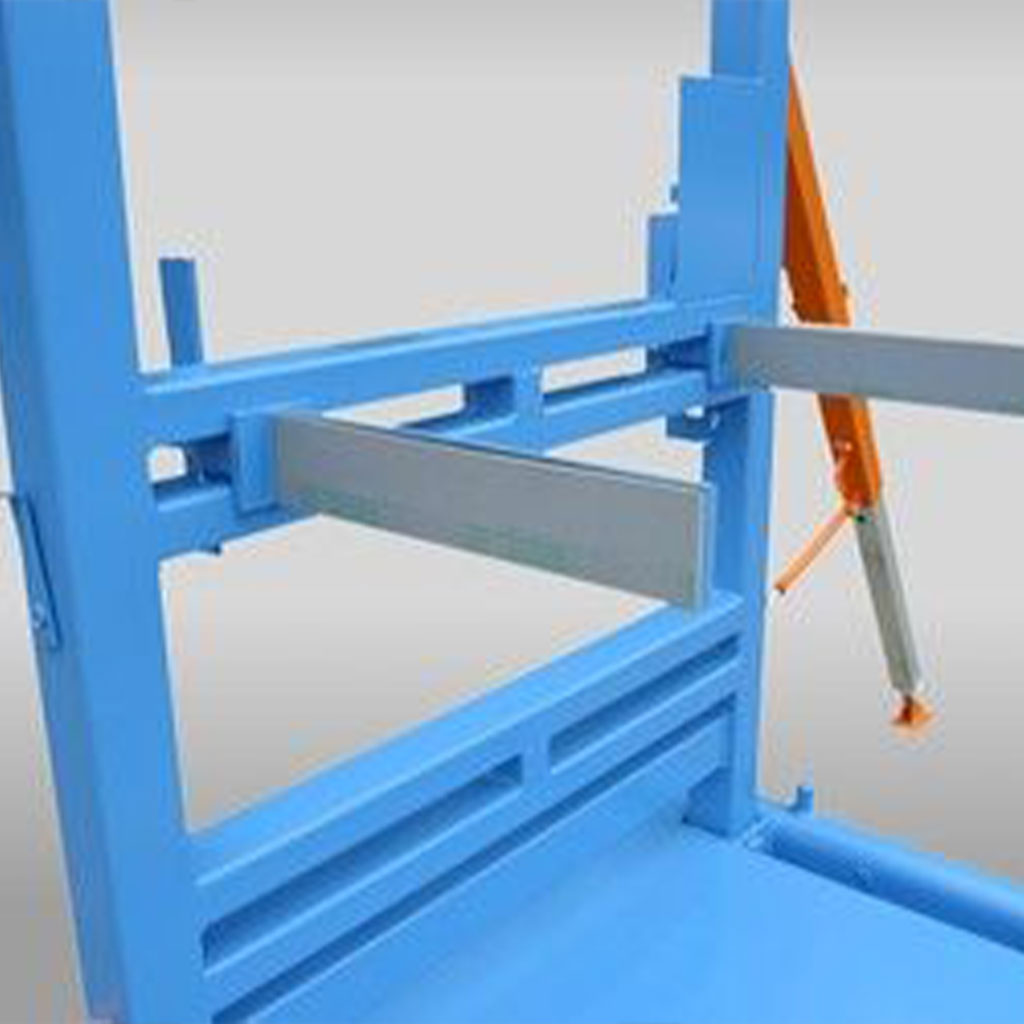

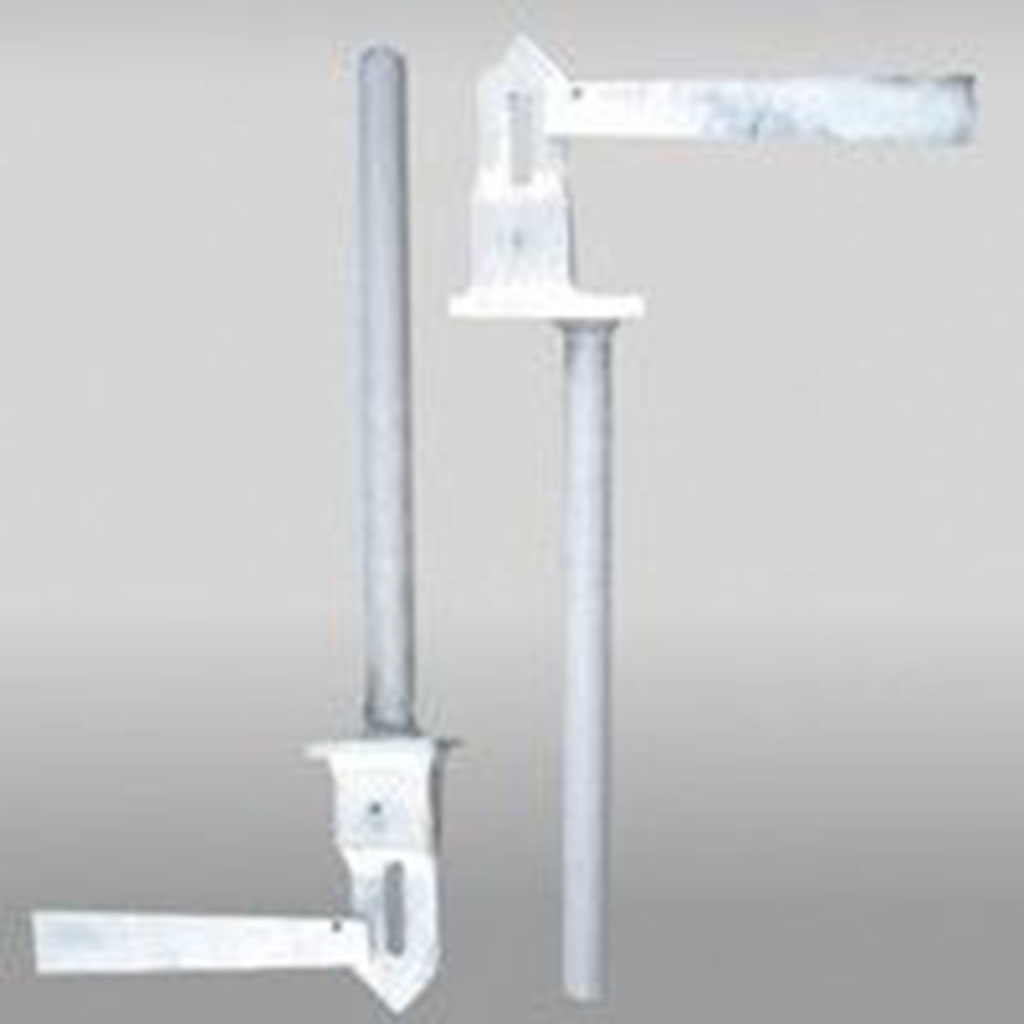

Safety pin & safety sword

To fix the transport elements to the gallows (guide trestle), we offer securing pins and securing swords as required. All R-Tech inloader pallets can be retrofitted with the support securing system.

Our wedge fixation has proven itself in many years of practical use (see safety standard).

Securing with stanchions

For maximum safety on complex concrete walls, we offer base frames with integrated stanchion pocket braces. Stanchions can be inserted in the required positions to stabilize the complex parts.

Requirements for base frames

We have developed individual solutions to protect the load during transportation.

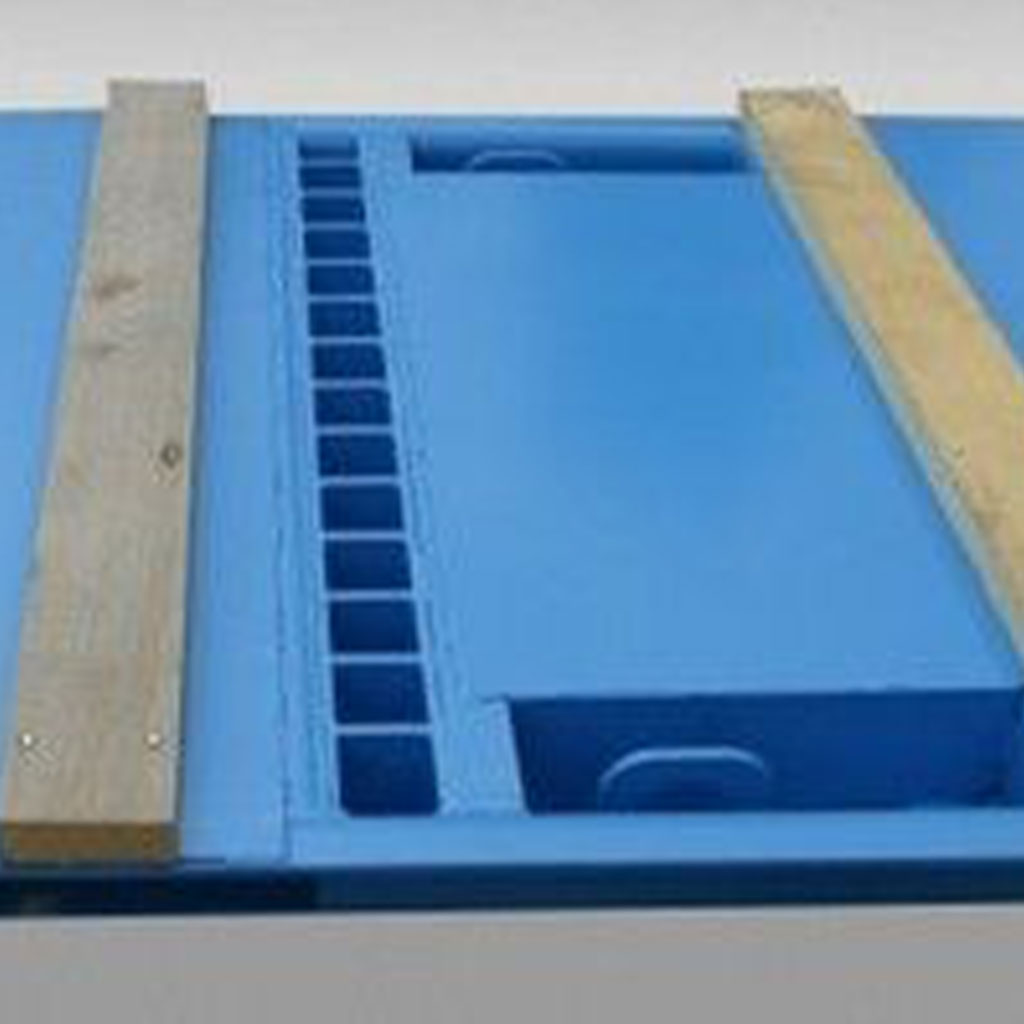

Base frame with sheet metal base and hard rubber support / with hard rubber support on cross member

Base frame with overall wooden support

Base frame with wooden support

Innovation exclusively from R-Tech

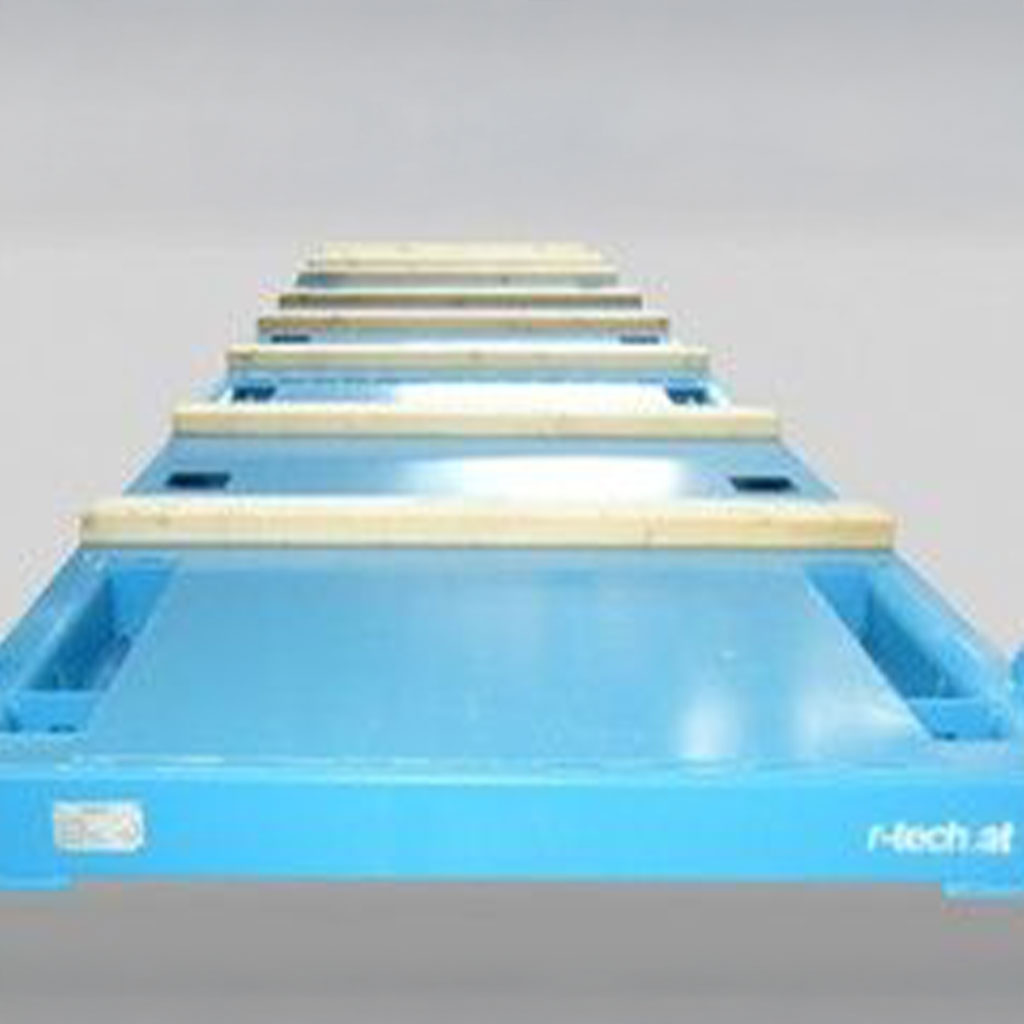

Specially developed telescopic pallet

The innovation from R-Tech, available soon.

Our telescopic inloader range was specially developed by R-Tech for the FAYMONVILLE PREFAMAX telescopic inloaders. – Exclusively from R-Tech!

Our tried and tested load securing elements are of course also available for the telescopic pallet. Loading length: 9.5 to 13.4 meters.

Efficient transportation option

Thanks to the modular design, all pallet variants can be transported stacked. This results in potential savings for return transports.

Internal loader pallets from R-TECH for use in precast construction

Are you looking for an inloader pallet that adapts perfectly?

We offer you our range of telescopic inloaders. Safety and efficiency are equally important to you? We offer you the solution for precast concrete parts, together with set-down pallets and turning devices.

Would you like comprehensive information and advice? Get in touch with us. We are here for you and support you with innovative, tailor-made solutions!