Wir stellen aus:

Unser Unternehmensvideo

Der Katalog von R-TECH

Die robusten Gestelle sind weltweit praxiserprobt und definieren aufgrund eigener Testverfahren neue Sicherheitsstandards bei Beladung und Transport.

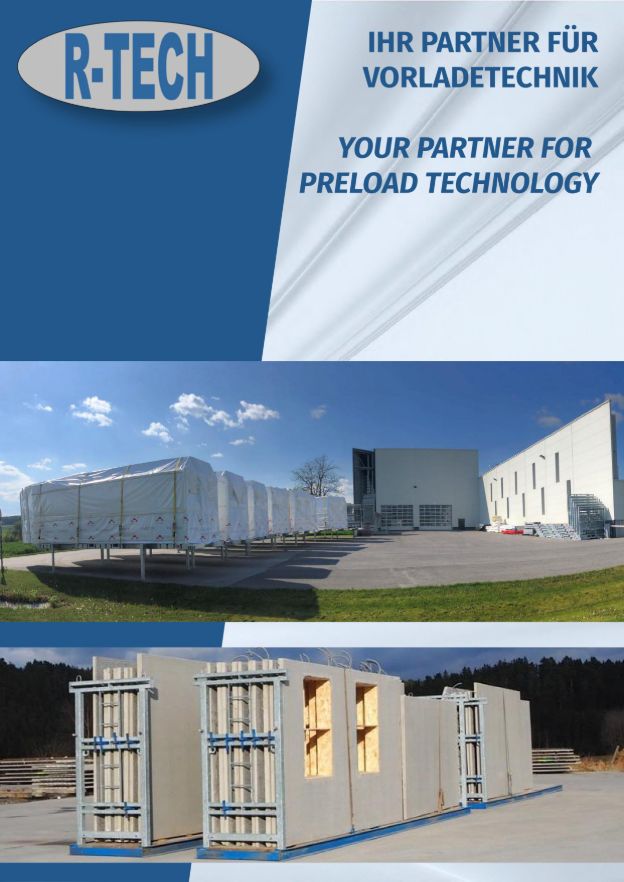

Innenladerpalette für Beton- und Holzfertigteile R-TECH Stahlbauges.m.b.H.

Seit über fünfundzwanzig Jahren fertigen wir Innenladerpaletten und Wechselbrücken (Absetzpaletten) für Fertigteilwände mit höchsten Sicherheitsstandards und bewähren uns im Bereich Stahlbau und Serienproduktion.

Wir setzen uns weltweit erfolgreich mit unseren Systemen für Standsicherheit durch integrierte Abstützsysteme ein, die sich im täglichen Umgang auf den Baustellen optimal bedienen lassen:

Von Innenladerpaletten und Wechselbrücken für Fertigteilwände aus Holz oder Beton bietet R-TECH Ihnen die Sicherheit und Effizienz für Ihre Produktion am Bau.

Transportsystem mit R-TECH Vorladetechnik für Beton und Holzfertigteilindustrie

Von Innenladerpaletten und Wechselbrücken (Absetzpaletten) bis zum Wendebock finden Sie bei uns robuste, praxiserprobte Gestelle und Technik. Damit definieren wir auf der Basis eigener Testverfahren neue Sicherheitsstandards bei Beladung und Transport im Beton-Bereich führend.

Die Problematik bei Transport und Lagerung von Beton-Fertigteilen ist bekannt: Sie sind in der Regel mehrere Meter hoch, von enormer Masse bei relativ schmaler Tiefenauflage. Standsicherheit ist ein absolutes Must-have auf der Baustelle, das durch Windböen und kompliziertes Handling gefährdet wird. R-TECH setzt mit praxisnahen Stabilitätstests dagegen und entwickelt Technik, die passt und hält.

R-TECH Paletten als Allrounder

Betonwände sowie Holzwände müssen transportiert, sicher gelagert und sicher aufgestellt werden. Wir von R-TECH bieten Ihnen ein umfassendes Leistungsspektrum von der Logistik über die Standsicherheit bis zur Verwaltung über Monitoring via App weltweit für den täglichen, industriellen, robusten Einsatz mit höchsten Sicherheitsstandards. Bei uns bekommen Sie:

- kunden- und produktspezifische Lösungen

- R-TECH Transportgestelle als Innenladerpaletten, Wechselbrücken und Absetzpaletten

- R-TECH Transportgestelle für schweren, langjährigen Betriebseinsatz

- R-TECH Transportgestelle ohne Nacharbeiten und mit optimal sicherem Handling

- R-TECH Transportgestelle ohne verdeckte Mehrkosten

- Wendevorrichtungen für Betonfertigteile als Wendebock

- Serienproduktionen nach Kundenwunsch und in gemeinsamer Entwicklung

Weltweit effizient und sicher mit Innenladerpaletten von R-TECH

Unser Ansatz ist jeweils kundennah, praxisbezogen und innovativ. Profitieren Sie von unseren Erfahrungen und unserem Know-how. Wir bieten Ihnen Sicherheit. Sie können effizient und kostengünstig kalkulieren.

Die von R-TECH entwickelten Sicherungselemente (Sicherungsschwert / Sicherungsdorn) mit Kunststoffüberzug vermeiden den direkten Kontakt zwischen Beton und Metall und reduzieren dadurch Transportschäden und Folgekosten. Mit jedem Transport auf R-TECH Paletten sparen Sie Zeit und Geld und erhöhen die Sicherheit für Ihr Team.

Sie haben Fragen oder einen Auftrag. Nehmen Sie Kontakt zu uns auf. Wir sind für Sie da.